Product introduction

DPP-350 automatic alu alu and alu plastic blister packing machine(two functional equipment) is an improved type of equipment our company recently launched, adopt the integrated control technology for frequency control and machine, electricity, light, gas . And in strict accordance with the pharmaceutical industry (GMP) standards for innovative design,the machine is in the leading level in the the domestic. The advanced function, simple operation, high capacity of the machine are the most ideal packaging equipment of large and medium-sized pharmaceutical companies, health care products and food industry in electronic packaging.Main function:PVC blister forming、automatic feeding、PTP aluminum foil flat press heat-sealing 、printing register control、batch number embossing、easy cutting line embossing 、blister plate blanking、Waste recycling.The machine is suitable for package of aluminum plastic (aluminum aluminum) blister package for pharmaceutical, chemical, light industry and food industry in tablet, capsule.

Product features

1.The whole structure adopts open layout structure, and the modular design has good station visibility and convenient maintenance and adjustment. Novel and safe appearance protection design is for safe operation.

2.With the heating plate temperature control, the main motor overload protection, PVC and PTP package material position detection, feeding storage position detection control, automatic protection shutdown if have fault.

3.The heating mechanism adopts the contact type version of the heating, the delay of the turning-on after the heating plate is put down, will limit the material waste in a stroke within; and reduce the heating power and heating temperature, save energy and enhance the stability of the plastic film, not easy to deformation.

4.Increase PVC rapid replacement material feeding platform, rapid material platform, whole guide, increase the overall practicality of equipment.

5.Molds concave groove positioning, rectangular design, positive pressure forming, micro edge blanking, replacement more convenient and quick. All parts of contact with drugs are made of high quality stainless steel and high quality aluminum alloy non-toxic materials, high-grade surface treatment process, texture emerging.

6.Cushion seal: when the machine stops, the cylinder will automatically rise the netted plate.The deformation of the bubble caused by heat radiation during the stay is eliminated, which is convenient for the cleaning of the netted plate, and the buffering effect of the super pressure is also beneficial to prolong the service life of the machine.

7.The upper and lower netted plate is heat sealed work in with each other: that is, both the positive and negative sides are dot like recalculate (also can be linear sealed), because the stress is equal, the plate is more smooth, and the sealing performance is improved.

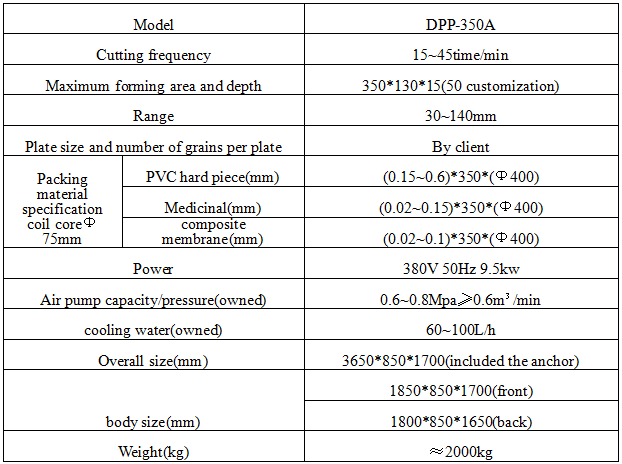

Product parameters

Product application

1. Pharmaceutical industry: In the pharmaceutical field, the DPP-350 packaging machine can be used to package various medicines, such as tablets, capsules, granules, etc., to ensure the stability and safety of medicines during transportation and storage.

2. Food industry: In the food industry, this packaging machine is suitable for the packaging of foods such as candy and chocolate, providing freshness and moisture-proof functions to ensure the quality and taste of food.

3. Daily necessities industry: For daily chemical products such as shampoo, conditioner, shower gel, etc., DPP-350 can achieve efficient blister packaging, enhance the visual appeal of the product, and facilitate consumers to carry and use.

4. Electronic products: For electronic products such as batteries, USB flash drives, headphones, etc., blister packaging can provide shockproof and anti-static protection to ensure the safety of products during transportation and sales.

5. Auto parts industry: In the production of auto parts, this packaging machine can be used to package some smaller parts, such as spark plugs, filters, etc., to ensure that the parts are intact during transportation and installation.

Tel:+86-15919644519

Mobile:+86-15919644519

E-mail: sales@xinglepm.com

Skype: gmpacky

Whatsapp: +86-15919644519